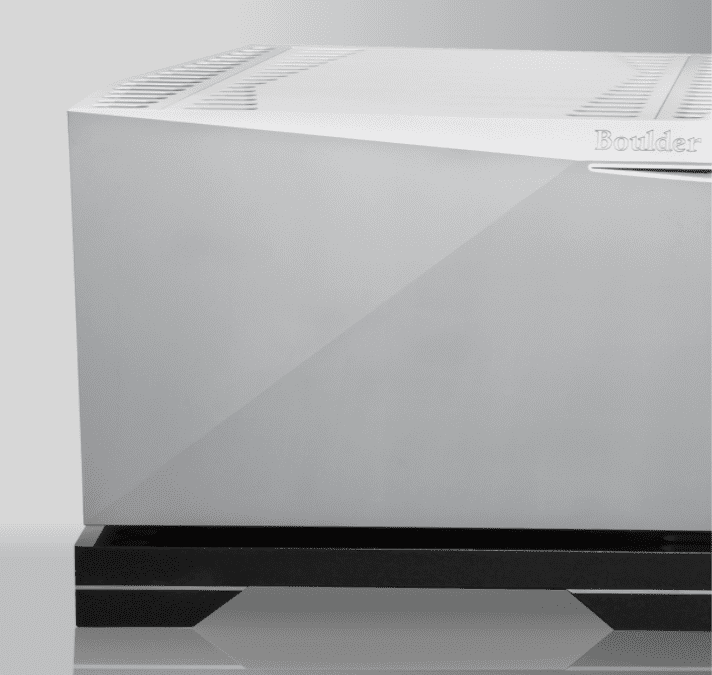

Signature Brand: boulder

ELEGANTLY HAND-CRAFTED

Every part of our products, every piece of metal, every circuit is created and assembled in-house by our own craftsmen and technicians. Boulder is the last audio manufacturer in North America to hold this degree of control over our own designs.

For over 35 years, Boulder has been building the world’s highest quality audio components near Boulder, Colorado. Early origins in broadcast and recording meant that record producers and recording engineers who listened day after day recognized the neutral and transparent performance that enabled the character of individual recordings to shine through the electronics. Over the years the company has made the gradual transition from professional to home audio. Having worked carefully to improve quality without compromise, all aspects of design, manufacturing, and assembly are now carried out in a purpose-built facility. Boulder’s independent ownership has also remained the same since its founding, meaning that new products will be developed by a team who adheres to the company’s core values for years to come.

the future

Under Jeff Nelson’s leadership, Boulder has grown and prospered for over 30 years. The company has also retained the invaluable experience of a number of employees who have been with the company since its earliest days. These dedicated craftsmen, technicians and designers breathe life into the original Boulder vision and make it a reality. Their enthusiasm ensures that the Boulder philosophy will continue as long as lovers of music and film desire to listen with the very finest audio components in the world.

With a new manufacturing space and ample room to grow, the future will see Boulder continue what Jeff started: identifying current shortcomings and then creating what will inevitably become the industry’s standard by executing every detail, from concept to completion, better than anyone else.

With distribution in more than 40 countries, Boulders are cherished by music and film lovers all over the world and are instilled with quality and value that transcend the passage of time.

With distribution in more than 40 countries, Boulders are cherished by music and film lovers all over the world and are instilled with quality and value that transcend the passage of time.

The Factory

In August of 2016 Boulder moved to a new manufacturing facility in Louisville, Colorado. At 23,000 square feet, the new factory is more than twice the size of the previous building and enables engineering and assembly operations to be more productive and efficient.

The current Boulder factory features the latest energy conscious lighting and ventilation systems, automated access and locking systems, three dedicated listening spaces, and a new production and machining area to improve what is already the highest standard in the industry for design, fabrication, and assembly.